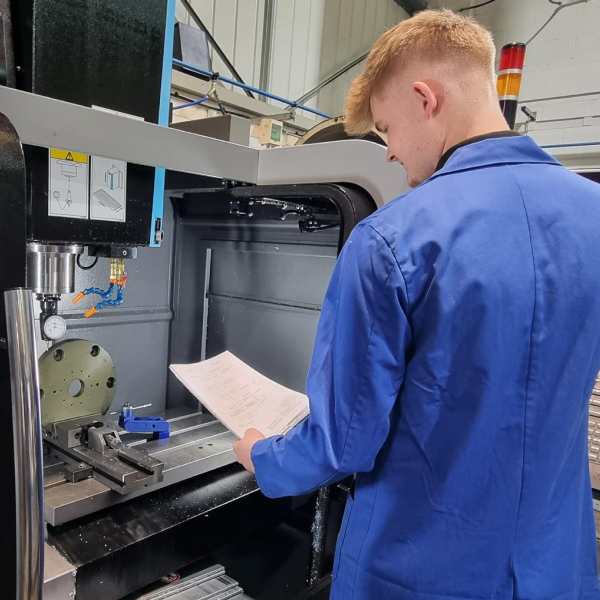

Quality Control

We inspect every component part that leaves DCV to a high standard, checking measurements, and finishes.

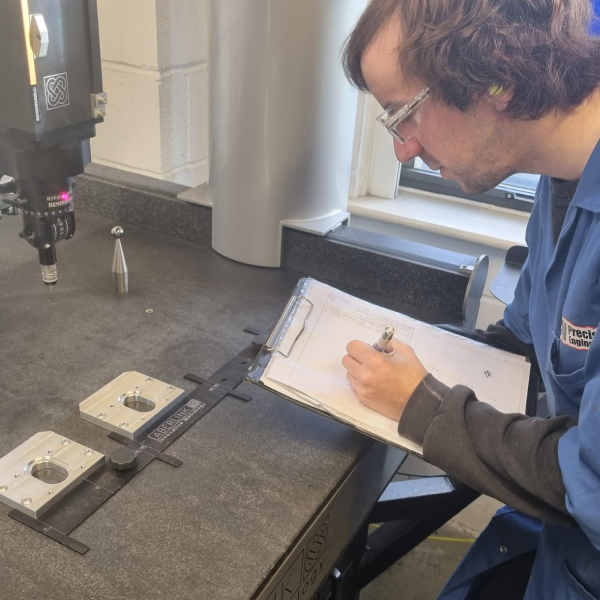

Our dedicated inspection area has a variety of measuring equipment from simple tools such as vernier calipers to advance tools such as the Aberlink Axiom Too CMM. All of the measuring tooling is calibrated to UKAS standards on a annual basis. We also look to continuously invest in quality control where if we come across a feature we can’t measure we will invest or make tooling to be able confidently measure to customer requirements.

Quality

To ensure we fully meet customers expectations our quality management system has been built to incorporate all criteria of the ISO9001:2015 accreditation.

Using Tricorn systems we follow the traceability route enabling us to track all the components from quotation to order.

Our materials are given serial numbers relating to a mill certificate, therefore, allowing full traceability.

We offer full inspection reports on parts manufactured by DCV if required, supplying certificates of conformity or CMM FAI reports.